How to Set Up Your 50 PSI Compressor for Tracheostomy Care

Using a 50 PSI compressor for respiratory support can be a game-changer, but setting it up correctly is crucial for safe and effective use. This guide will walk you through each step, ensuring your compressor is ready to provide the support you need.

Gather Your Supplies:

Before you begin, make sure you have all the necessary components:

- 50 PSI Compressor

- Metal T-connector

- Air hoses (x2)

- Mask

- Drainage bag

- Humidifier bottle

Gather Your Supplies:

Start by examining the compressor for any visible damage or wear. Make sure all components are securely attached and that there is adequate ventilation around the compressor.

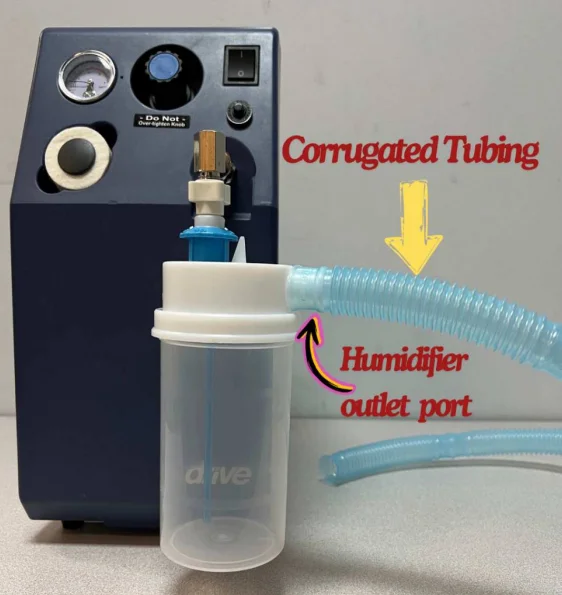

Set up the humidifier bottle

Inspect the humidifier bottle for any damage or debris and ensure all components are present. Fill the bottle with distilled or purified water to the indicated fill line. Make sure the T-connector is tightly connected to the compressor and screw the humidifier bottle onto the designated port/connector.

Connect the Corrugated Tubing

Check the tubing for any damage and ensure it is clean. Firmly push the tubing over the outlet port of the humidifier bottle until it is snug and secure

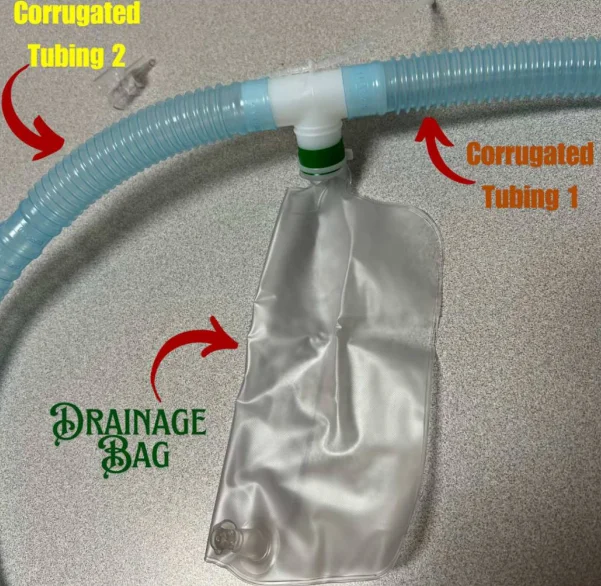

Connect the Drainage Bag

Connect one end of the drainage bag to the corrugated tubing attached to the humidifier bottle, and the other end to the second corrugated tubing.

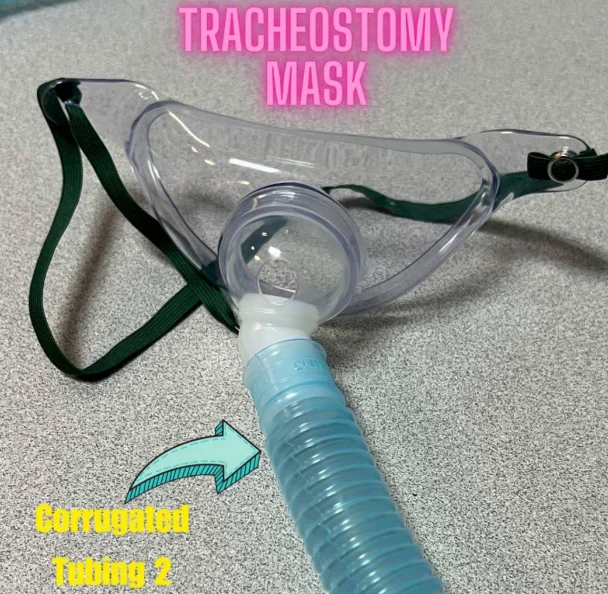

Connect the Tracheostomy Mask

Connect the tracheostomy mask to the other end of the corrugated tubing attached to the drainage bag.

Troubleshooting:

If you encounter any issues with your 50 PSI compressor, here are some troubleshooting steps:

- Verify the power cord is securely plugged into a functioning electrical outlet.

- Ensure the compressor’s power switch is in the “on” position.

- Ensure the pressure regulator is set to the desired 50 PSI setting.

- Make sure the humidifier is tightened on the T-connector without leaks, but avoid over-tightening.

- Confirm the pressure gauge is functioning accurately.

- Listen for hissing sounds that may indicate air leaks.

- Inspect all hose connections, fittings, and seals for air leaks.

- Ensure all hoses and tubing are free from kinks or blockages.

- If any issues persist, contact UniversalMed Supply for assistance.

Cleaning and Maintenance:

Regular cleaning and maintenance are essential for optimal performance:

- Wipe down the exterior with a clean, damp cloth, avoiding harsh chemicals.

- Clean the air intake filter regularly using compressed air or by gently tapping it. Replace if it’s excessively dirty or damaged.

- Check the rear filter occasionally and replace it every 6-8 months if needed.

- Store the compressor in a clean, dry place when not in use

FAQs:

Q: How do I set the pressure on my 50 PSI compressor?

A: Use the pressure regulator knob located near the pressure gauge. Turn clockwise to increase and counterclockwise to decrease the pressure.

Q: Why is my compressor not building pressure?

A: Check for leaks, clogs in the air intake filter, and ensure the pressure regulator is set correctly

Q: How often should I perform maintenance?

A: Inspect and clean the air filter, check for leaks, and inspect hoses and connections monthly.

Q: What should I do if my compressor overheats?

A: Turn it off immediately and allow it to cool down. Check for proper ventilation. If the problem persists, contact UniversalMed Supply.

Q: What if my compressor is making unusual noises?

A: This could indicate issues with the motor or other components. Turn it off and inspect for visible problems. If you can’t identify the issue, contact UniversalMed Supply.

Q: Can I use extension cords with my compressor?

A: It’s not recommended, as they can cause voltage drops and motor damage.